Unveiling | the Secrets Behind ZXTLCD Video Wall Displays

In 2010, ZXTLCD introduced the LCD splicing screen and has since maintained a high market share nationwide. Behind this success lies ZXTLCD strict control over the excellent craftsmanship and stable quality of LCD splicing screen products. It is precisely because of ZXTLCD constant focus on product quality and continuous pursuit of technological innovation that it has earned a good reputation among users.

Throughout the development of LCD video wall displays, ensuring stable operation, breakthroughs in picture presentation, satisfactory splicing effects, and having a complete process to enhance delivery experience have always been the focal points of customer concerns.

How can the stable and efficient operation of LCD video wall displays be ensured?

The stable and efficient operation of the entire system is the primary consideration during product design. ZXTLCD video wall displays have proposed various solutions with the goal of stability, safety, and diverse functionality in the application of key components.

The main control board solution enables multi-chip collaborative analysis and realizes various data processing functions. The power board solution ensures the normal display of the screen and provides the necessary working current for the system. The structural design achieves high anti-electromagnetic interference, heat dissipation, moisture resistance, and dustproof capabilities through a layered design. The module solution determines key parameters such as the display effect, seams, brightness, and lifespan of the splicing screen.

Through the combined operation of these solutions, product performance is improved while reducing power consumption, increasing the reliability of actual product usage, enhancing energy efficiency and display effects, allowing the screen to run 24/7.

How should LCD screens adapt to complex real-world usage scenarios?

In response to the complexities of real-world usage scenarios and to meet users’ display requirements for different environments, purposes, and visual preferences, ZXTLCD’s research and development engineers have analyzed and sorted the materials used by a large number of end-users based on their feedback. They have summarized commonly used LCD screen scene modes and repeatedly adjusted and deliberated on the image parameters in each mode, ultimately determining the preset parameters for each scene mode. This allows for one-click mode switching for scenarios such as movies, presentations, and surveillance, meeting the demands for brightness, contrast, color saturation, clarity, and other parameters.

The screens also support multiple analog and digital signal inputs, including VGA, BNC, SDI, DVI, HDMI, DP, and more.

How to overcome the “inherent problem” of inconsistent color display in LCD screens?

Due to the characteristics of individual panel splicing and factors such as materials and processes, LCD screens often face the issue of “color inconsistency,” resulting in a display with various colors.

To improve the visual experience, ZXTLCD has abandoned the traditional manual adjustment of screens and adopted two automated calibration schemes for internal mura and inter-screen color difference. By using algorithms to enhance product display effects, adjustments are made to each pixel based on image data and screen status, ensuring balanced and consistent screen splicing, uniform grayscale transitions, concentrated color coordinates, improved overall brightness, and more.

How to ensure the full-process production and after-sales of LCD products?

A good product should maintain the same level of quality as the design samples, which requires strict quality control during mass production. ZXTLCD video wall displays adhere to high standards and strict requirements in terms of manufacturing processes, materials, and design. They have complete capabilities for automated assembly line production, quality control, and MES execution throughout the entire process, ensuring consistency and display effects of the products before leaving the factory, while also emphasizing cost-saving in labor.

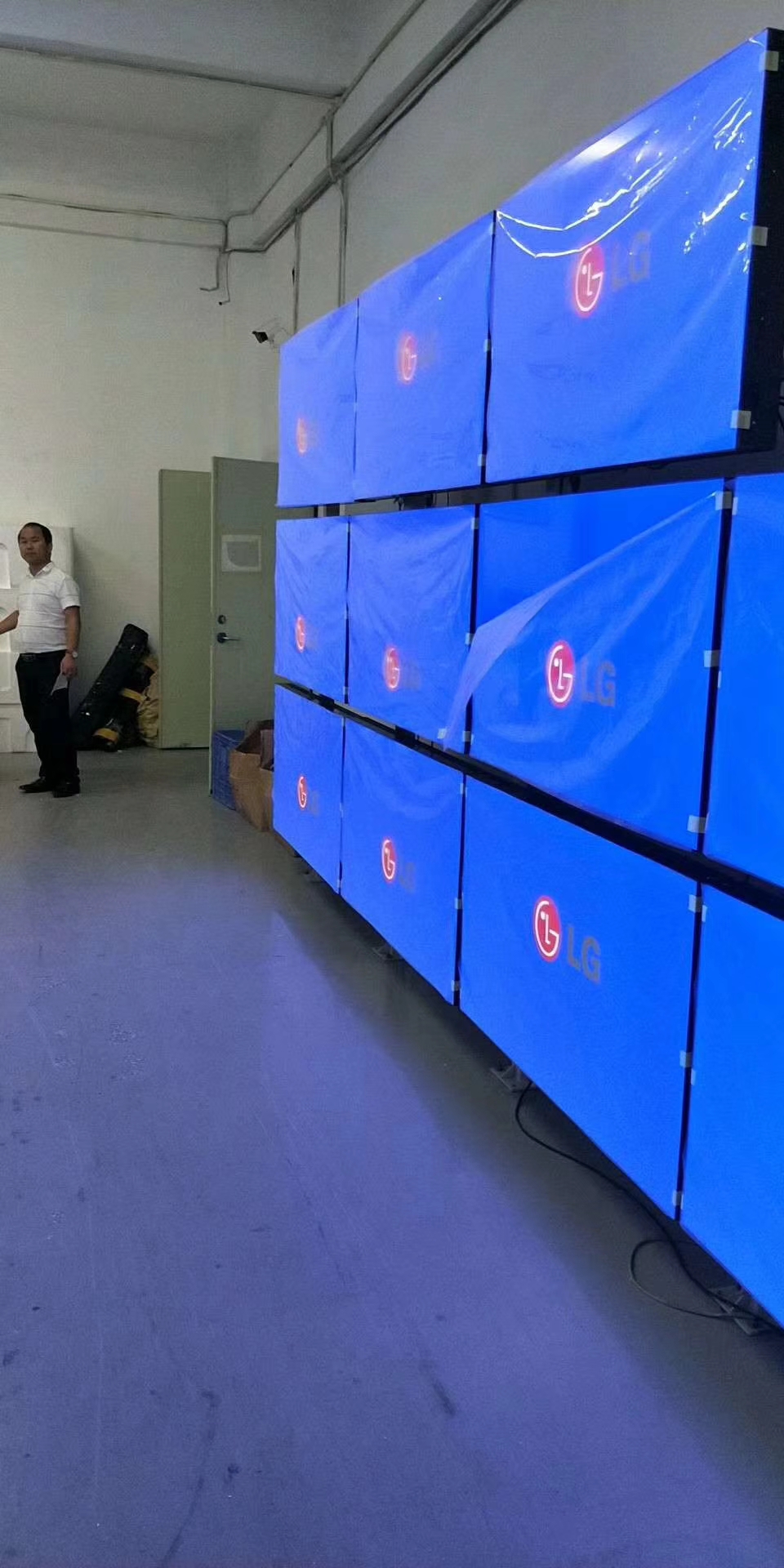

In addition to production, ZXTLCD places high importance on service quality. Whether it is in delivery, transportation, installation, or after-sales, they provide customers with standardized, complete, efficient, and prompt service processes, continuously improving the customer experience.

From 1080P to 4K Ultra HD, from wide gaps to narrow seams, ZXTLCD video wall displays are committed to capacity upgrades and fearlessly addressing industry pain points. With strict standards throughout the design, production, and after-sales processes, they prioritize customer experience, providing clearer, easier-to-operate, and higher-quality display devices. They expand the commercial display market and embrace the “vision” of the future.