2×3 Video Wall Installation Case: Pre-steps

Delivery Schedule, Installation and Commissioning Plan, and Guarantee Measures

(1) Schedule

Within 10 work days after the procurement contract is signed, complete the installation, commissioning, pass the testing, and deliver to the purchaser for use.

(2) Installation and Commissioning

Ergonomic Design

The optimal viewing angle design for LCD large screen video walls is based on ergonomic principles. The ergonomic design considers the pedestal height, horizontal viewing angle, and vertical viewing angle of the video wall large screen system to obtain the best viewing angle and provide users with the most professional visual experience.

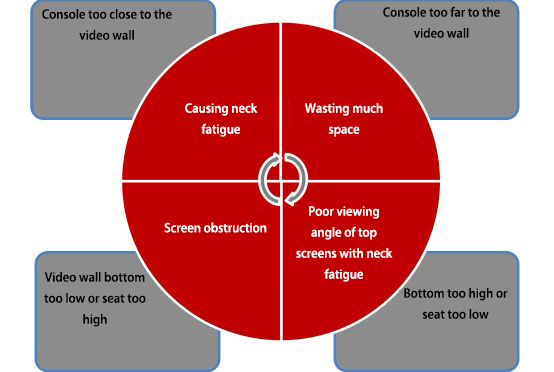

Principles for Designing the Optimal Screen Position:

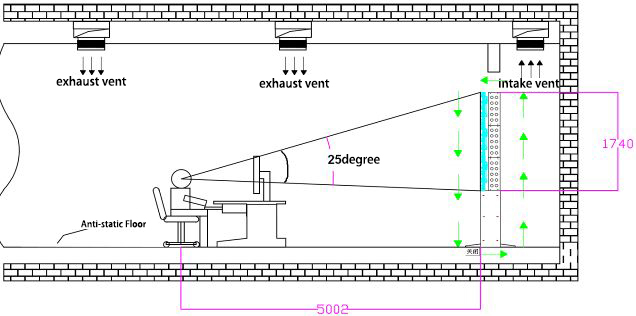

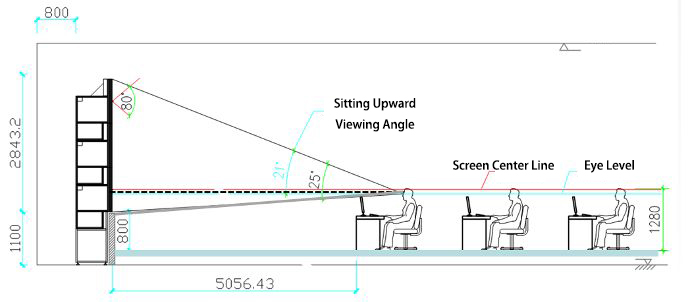

Vertical 25-Degree Principle

When the viewing angle is ≤25 degrees, there is no need for head movement, which is ergonomically favorable and prevents spinal fatigue during extended viewing. At this angle, the distance to the screen is considered the closest viewing distance, which is the nearest distance between the console and the screen.

Horizontal Line-of-Sight Principle

The horizontal line of sight of the human eye should be perpendicular to the projection screen to achieve the best screen viewing effect. For LCD large screen setups, the midline of the bottom screen of the stack should be used as the reference. The typical height of the human eye’s horizontal line of sight in a seated position is around 1.28 meters. The midline of the bottom screen of the LCD large screen setup should be as close as possible to this height.

Video wall installation follows these two principles, resulting in calculated pedestal heights and distances between the console and the screen that are in line with ergonomic design principles, providing customers with the most comfortable viewing angles and the best viewing effects.

(3) Construction Standards

1.1 Power Supply Requirements

For this setup, the video wall consists of 6 units of 46-inch LCD screens arranged in a 3 (rows) by 2 (columns) configuration. The specifications are as follows:

The LCD large screen video wall system requires a stable single-phase 220V stabilized power supply. Each LCD unit’s rated power is 139W, and each splicing controller system’s rated power is 300W. The total rated power of this system is 2000W (including redundancy).

Provide at least 2 units of 220V, 5100W total power air switches for the distribution cabinet of the LCD large screen display system, and at least 21 units of 220V power air switches for the cabinet equipment. High-quality electrical products should be used for all electrical switches.

Provide at least 2 220V power sockets under the rack of each column of the LCD large screen display system equipment, with each socket providing power for three to four LCD screens.

Provide at least 3 220V/10A power sockets beside each cabinet.

Ordinary maintenance sockets and lighting power lines should be equipped with ground fault protection switches.

All electrical materials in the equipment room should have production certificates approved by the fire department, and all electrical wires and cables should be flame-retardant or difficult to ignite.

Note: Adequate operating space should be left above the wall and on both sides of the wall. Considering ventilation and heat dissipation, room layout adjustments are recommended to connect the space behind the LCD large screen with the equipment room, ensuring both ventilation and easy maintenance.

1.2 Air Conditioning Requirements

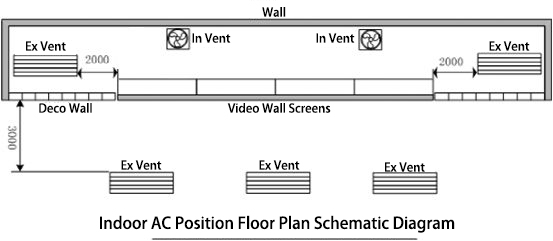

If conditions permit, the installation room for the video wall LCD large screen system can use constant temperature and humidity air conditioners or split air conditioners with both cooling and heating functions (central air conditioning systems in the building should also be configured if available).

For air conditioners (central air conditioning or cabinet-type air conditioning) located in the maintenance aisle of the LCD large screen display system, the air outlet should be positioned far away from the rear of the cabinet, and the cold air from the air outlet should not blow directly onto the screen. It should blow in a direction away from the screen to avoid uneven temperature distribution and condensation on the screen.

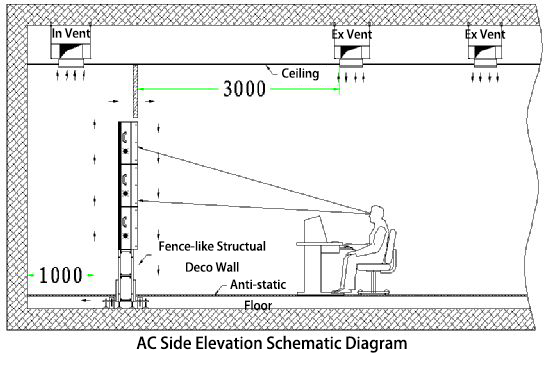

Ideal air conditioning design requirements (in an ideal state): The air supply and return ducts of the central air conditioning in the front hall and the maintenance aisle behind the LCD large screen display wall should be designed as a single duct. All air conditioning supply outlets should be about 3 meters away from the LCD large screen display wall and should not blow directly at the wall. A single switch for the air conditioning in the front and rear maintenance aisles of the LCD large screen display wall should be centrally installed. When using the air conditioning, the supply should be turned on or off simultaneously to prevent significant temperature differences caused by forgetting to operate a switch. Additionally, there should be at least 2 exhaust fans behind the maintenance aisle of the LCD large screen display wall, directing air circulation towards the outside. This ensures air circulation between the front and rear of the LCD large screen display wall, preventing uneven temperature distribution and condensation on the screen wall (see the projection room air conditioning design layout plan). It is recommended that the installation site of the LCD large screen be designed with a “facade schematic diagram of air conditioning design method one-sided”.

In areas with high humidity, dehumidifiers should be installed in the equipment room to maintain the required relative humidity.

Before on-site installation of the LCD large screen display system, the air conditioning system and fans at the installation points should be operated for 1 week to ensure that dust is cleared from the air conditioning ducts.

1.3 Temperature and Humidity Requirements

The maintenance aisle of the LCD large screen display system should have good air conditioning and air circulation, ensuring that temperature differences do not cause condensation between the front and rear of the video wall screen system.

The ideal operating environment temperature for the LCD large screen display system is 22°C ± 4°C, with an ideal relative humidity of 30% to 70% without condensation. Sudden temperature and humidity changes should be avoided, and any changes in temperature and humidity should occur gradually.

Prolonged use in a high-humidity environment (temperature difference between the equipment room and the screen hall) can lead to the accumulation of moisture and droplets on the surface and edges of the LCD screen. Moisture may seep into the interior of the LCD and corrode its internal structure, resulting in LCD leakage as shown below.

Improper usage or inadequate maintenance leading to any damages (including but not limited to equipment damage and losses incurred by the user or third parties) will not be covered by the company’s warranty. In the spirit of a friendly cooperative relationship, issues can be resolved through negotiation.

Attention:

- When the system is shut down, please turn off the air conditioning in the equipment room to maintain consistent indoor and outdoor temperatures.

- After a long shutdown, check for condensation or droplets on the screen before restarting.

- If condensation or droplets are found, do not wipe with a wet cloth. Use absorbent paper towels and promptly notify the company.

1.4 Lighting Requirements

To achieve optimal viewing effects in the viewing area, it is recommended to create a dark area within four meters in front of the screen, and daylight fluorescent lamps should not be installed. It is advised to install concealed ceiling lights parallel to the screen arrangement, with separate controllable on/off switches. The lighting should not directly shine onto the screen, and lights should be positioned to minimize illumination on the screen. Lighting design should aim to be directed away from the LCD large screen.

Lighting throughout the entire hall should be divided into groups controlled parallel to the screen’s direction. Avoid using strong light sources, and arrange the lights in a way that provides sufficient lighting intensity to the working area without significantly affecting the screen.

Necessary measures should be taken to block light from entering the hall on both sides (such as windows). (Sunlight has the greatest impact on image quality.)

1.5 Interior Decoration Requirements

The recommended wall thickness for the screen window decoration of the LCD large screen display system is 80mm, with a sturdy and straight wall that does not deform around the window.

Before installing the LCD large screen, the wall for screen window decoration should have reserved dimensions of (1024×3+50)mm horizontally by (593.3×3+50)mm vertically. This means adding an extra 50mm to each side of the actual dimensions of the entire screen wall. When splicing more than 10 rows, the reserved dimensions should be larger than the total dimensions of the spliced wall to facilitate installation (see project construction drawings).

After the LCD large screen display wall is installed, the on-site decoration unit should fill the gaps around the screen with a gap of no more than 1 meter (with the principle of no light leakage) and perform necessary finishing. The overall decoration style should be fresh, with cool color tones, and a simple and bright design. Regardless of the ceiling material used for decoration, the color should be milky white, silver-gray, or light gray, with a matte finish. The surface must not have strong reflections. The wall panel colors should be vibrant, with darker lines, and sound-absorbing materials should be placed in appropriate areas. The wall surface should have a matte finish. The floor is best covered with anti-static flooring or carpet, with a darker color or other non-reflective floor material.

Before installation, ensure that the site environment is clean, tidy, dust-free, and free from paint or lime residue. No high-altitude operations should be conducted within the installation range of the display wall. The fire protection system should undergo safety testing, the air conditioning should be operational, and the electrical system should be stable and safe.

1.6 Requirements for Equipment Maintenance Aisle and Flooring

There should be a maintenance aisle of no less than 1 meter behind the LCD large screen display wall, equipped with independent lighting control.

The floor surface of the LCD large screen display wall and the maintenance aisle should be coated with anti-dust paint to effectively prevent dust from affecting the optical equipment.

Ensure that the installation site for the LCD large screen display wall has a flat surface, with an unevenness not exceeding ±3 millimeters.

If the wall behind the maintenance aisle of the LCD large screen display system is a glass wall or there are glass windows on the sides, use thickened blackout cloth as curtains for shading and heat insulation to avoid direct sunlight.

1.7 Load-Bearing Requirements

Refer to the data in the table below:

| Unit Size (Lego-sylte) | 55-inch | 46-inch |

| Single Unit Weight | 43kg | 38.5kg |

| Pedestal Weight | 12kg | 10kg |

| 1st Floor Load-Bearing (Including Pedestal) | 220kg/m² | 348kg/m² |

| 2rd Floor Load-Bearing (Including Pedestal) | 392kg/m² | 348kg/m² |

| 3rd Floor Load-Bearing (Including Pedestal) | 564kg/m² | 502kg/m² |

| 4th Floor Load-Bearing (Including Pedestal) | 736kg/m² | 656kg/m² |

| 5th Floor Load-Bearing (Including Pedestal) | 908kg/m² | 810kg/m² |

| 6th Floor Load-Bearing (Including Pedestal) | 1080kg/m² | 964kg/m² |

1.8 Dust Protection Requirements

During installation, commissioning, and use of the LCD large screen display system, ensure that the work area maintains a clean environment with a dust concentration similar to that of a normal office.

1.9 Grounding Requirements

Dedicated grounding points should be set up near the LCD large screen display system equipment and cabinet equipment.

The joint grounding resistance of the equipment room should not exceed 3 ohms.

1.10 Fire Protection Requirements

The equipment room should be equipped with fire detection devices (temperature and smoke sensors) and a gas fire extinguishing system. Fire nozzles should be about 1 meter away from the display cabinets, and water spray fire nozzles should not be used. Instead, a mist fire extinguishing agent should be used.

Fire equipment installation should be carried out by professional installation and construction units.

1.11 Magnetic Field Requirements

The electromagnetic interference field strength and magnetic field interference environment field strength in the working area of the LCD large screen display system should comply with the design specification requirements of the PRC for computer room design (GB50174-93).

1.12 Comprehensive Wiring Requirements

Strong and weak electrical wire ducts should be strictly separated and should not intersect.

Weak electrical wire ducts should not use conduits.

Smooth transitions should be maintained between wire duct connections, and there should be no burrs or sharp corners.

Wire ducts should have good common grounding and shielding.

Strong and weak electrical wire duct installation should be carried out by professional installation and construction units.

Wiring for the power supply of the display wall should be routed around the perimeter of the display pedestal to avoid conflicts with the support feet of the pedestal. No pipes or cables larger than 50mm in height should be laid under the pedestal.

1.13 LCD Large Screen Wall Installation and Fixation Requirements

The pedestal of the LCD large screen display system should be directly installed and fixed on the cement floor and not on an anti-static floor.

The LCD large screen display system should be connected to the reinforced concrete wall behind the display wall through supporting rods.

1.14 Installation Precautions

1.14.1 Use of Power Cables

Do not damage the power cable, place heavy objects on it, stretch it, or bend it excessively. Additionally, do not extend the power cable. Damaging the power cable may cause fires or electric shocks.

Use only the power cable provided with the ultra-narrow bezel LCD display unit.

Do not pull out or insert the power plug with wet hands, as it may result in electric shock.

Unplug the power cable if not in use for an extended period.

Do not attempt to repair the power cable if it is damaged or faulty. Contact the authorized service center for repairs.

1.14.2 Cleaning and Maintenance

Before cleaning the ultra-narrow bezel LCD display unit, make sure to unplug the power cable. Do not attempt to maintain the product yourself; opening the machine cover exposes you to high-voltage electricity or other hazardous elements. Maintenance must be performed by professional service personnel.

To clean the LCD screen panel of the ultra-narrow bezel LCD display unit:

Use a non-shedding dry cloth to wipe the screen. This is to prevent damage to the screen surface coating. Do not use synthetic fiber cloths or cleaning agents.

Do not wipe the housing with benzene, thinner, or other chemical products. Do not spray volatile substances, such as insecticides, on the housing. Do not let the housing come into prolonged contact with plastic or rubber materials. Do not use synthetic fiber cloths, cleaning agents, or wax.

Please note that some parts of the text might be context-specific or require further clarification based on the specific technical and industry knowledge of the reader.